|

Room Temperature Curing, One-Part Silicone Rubbers |

|

1

Materials, Chemicals, Time Needed 1

Materials, Chemicals, Time Needed |

|

- Scotch tape, pH indicator paper, spatula, water-color paints

+ brush

- 3 U-shaped profiles or matchboxes

- 3 thermometers

- WACKER Silicon ELASTOSIL® E43, Xi, F, N

- WACKER Silicon ELASTOSIL® N199, Xi, F, N

- Calcium sulfate

Allow about 20 minutes to prepare the samples. The experiment

will take around 40 minutes overall. The samples will need

approx. 1 day to fully cure.

|

|

2

Procedure and Observations 2

Procedure and Observations |

|

|

|

Cover

the ends of two U-shaped profiles with adhesive tape.

Fill

one with ELASTOSIL® E43 and press the

compound down with a wet finger. Do the same with the

second profile,

using ELASTOSIL® N199.

Fill the third

profile with gypsum, and scrape off the excess with

a spatula. If no profiles are available, use empty matchboxes.

Place

a thermometer in each sealant, and place a moistened strip of

pH indicator paper on the edge of the profile (see Photo

1). |

|

| Fig.: 1 Filling a

U-profile with sealant |

|

|

| Photo 1: Experimental

set-up |

|

|

|

|

During

the experiment, monitor the temperature and the change

in odor

of each sealant for about 1 hour and tabulate the results.

After

final curing, check the samples for impact strength,

consistency and ease of overpainting with water-colors

(see Photo 2). |

|

Photo 2: Gypsum and silicone sample after painting

with water-color |

|

| Tabulate these results as well. The following

observations were made when the experiment was repeated several

times: |

|

|

|

| Measurements taken as the samples

were curing revealed that the temperature of all three samples

rose by around 1.5 °C. |

|

|

|

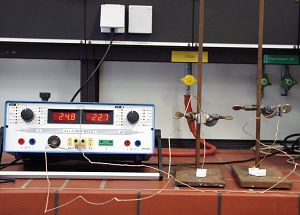

The

temperature changes plotted in the adjacent diagram

were measured with the "All-Chem-Misst" classroom

instrument and dedicated software (see Photo 3).

The measurements are mainly intended to reflect the

change in temperature. As gypsum cures, the temperature

rises sharply at first and then drops continually

until it remains almost constant (see diagram). In

contrast, the temperatures of the silicones changed

by different amounts and followed no particular pattern

(see diagram). |

| Photo 3: Setup for "All-Chem-Misst" measurements |

|

|

|

|

|

|

|

|

|

|

3

Discussion of Results 3

Discussion of Results

|

|

The test observations (see Table

1) reveal clear differences between gypsum and the two RTV-1

silicone rubbers. The two silicone rubbers cure by reacting in

several stages with the moisture in the air to form elastomers

(see Part 5 Supplementary Information). The cured material has

a soft, rubbery consistency and is elastic.

The acrid odor and the acidity of ELASTOSILS ® E43

stem from the fact that this system contains an acetoxy-based crosslinker

that releases acetic acid during the first hydrolytic reaction

step.

ELASTOSIL® N199, in contrast, is a neutral system. Water-colors

adhere poorly to silicones and can be easily washed off because silicones

are highly water repellent and have a non-stick effect (see also the following

experiments: "Water-repellent properties of

silicone fluids", "Silicones

in masonry protection" and "Silicone-coated

paper").

When gypsum cures, water molecules are incorporated into the ionic lattice

of the calcium sulfate. The calcium sulfate CaSO4 is thereby

converted into calciumsulfate dihydrate (gypsum) CaSO4 · 2

H2O. Because gypsum is an ionic compound, it is brittle and

breaks when subjected to mechanical force, such as a hammer blow.

The observed change in temperature accompanying the curing of gypsum may

be explained as follows: The temperature rise is due to Coulombic forces

between the water dipoles that penetrate into the ionic lattice and ions.

Some of the heat released is needed for evaporating the excess water. The

rest of the heat escapes to the surroundings. As a result, the gypsum cools

down.

The differences observed in the temperature changes accompanying curing

of the silicone rubber are the manifestation of several exothermic and

endothermic processes. These vary in nature and extent with the materials

employed and the method of preparation. Hydrolysis of the side groups (e.g.

acetoxy groups) and condensation of the silanols are exothermic reactions

whereas evaporation of the by-products (e.g. acetic acid) are endothermic

reactions. This leads to totally different, non-uniform temperature changes.

The properties we have just observed indicate that gypsum would not make

a good jointing material for joints subject to movement and stress due

to the fact that it is not elastic. It is suitable, however, for purely

decorative joints that involve no movement and are likely to be painted.

As for the two RTV-1 silicone rubbers, which make good "working joints," the

choice of which one to use depends on the by-products.

For example, ELASTOSIL® E43 would not be suitable for joining

two bits of marble as the acetic acid by-product would attack the marble

and impair the joint quality. |

|

4

Tips and Comments 4

Tips and Comments

|

|

- The experiment can be speeded up by omitting

the “long-term” temperature measurements and

simply measuring the rise in temperature at the start of

curing.

This can be used to demonstrate that exothermic reactions

predominate during both curing of gypsum and curing of

silicones.

- The experiment

could be extended by studying the influence of atmospheric

moisture on curing. To do this, fill a further U-profile

with an RTV-1 silicone in parallel to the experiment above,

store in a desiccator over dry silica gel under a water-jet

vacuum.

Note that the time needed for curing increases. When this

experiment was performed on ELASTOSIL® N199, three days

were needed for curing, whereas only one day was needed when

it was performed

in air. Curing never fully failed to materialize. The reason

is that the water-jet pump cannot remove all the atmospheric

moisture, and curing only requires small amounts of water.

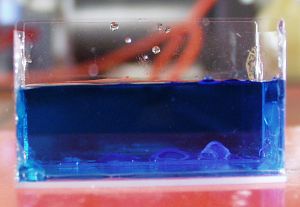

- Another

variant is to make an aquarium using RTV-1 silicone.

Make the aquarium by using ELASTOSIL® E43 or N199 to join

five grease-free glass plates (cleaned with acetone or

ethanol) at right angles to each other (photo 4). When curing

is complete,

test that it is leakproof. A similar experiment was very

successful, as seen in photo 4.

|

|

|

| Photo 4: Glass plates bonded together

with ELASTOSIL® silicone |

|

5

Supplementary Information 5

Supplementary Information

|

|

Room temperature curing, one-part silicone

rubbers, also known as RTV-1 grades (1-part room-temperature vulcanizing) already contain all the ingredients necessary

for curing, such as polyorganosiloxanes, crosslinkers and fillers.

The curing process, which releases by-products, only takes

place

on exposure to atmospheric moisture. RTV-1 silicone rubber

compounds are made by making hydroxy-terminated polysiloxane

molecules

react with crosslinkers to form curable products (see Fig.

2). |

|

| The standard base rubber compound is a polydimethylsiloxane

(R = CH3).

Table 2 shows the most common types of crosslinkers (RSiX3)

along with examples of the X group. |

|

| Type

of crosslinker |

X

group (Name) |

X

group (formula) |

| Acidic |

Acetoxy |

|

| Octoate |

|

| Neutral |

Amide |

|

| Oxime |

|

| Alkoxy |

|

| Alkaline |

Amine |

|

|

|

| Curing proceeds in the presence

of atmospheric moisture by the mechanism shown in Fig. 3. The

by-products vary with the type of crosslinker employed. Crosslinking

between silicone macromolecules occurs in subsequent reaction

stages and involves residual X groups. |

|

At the macroscopic level, curing starts on the surface of

the silicone rubber with the formation of a skin and gradually

works its way into the compound. Premature crosslinking is

prevented by the use of sealed packaging, such as tubes and

cartridges.

As shown in Fig. 4, the higher the content of moisture in the

air, the higher the curing rate.

|

|

|

| Fig. 4. Curing rate of ELASTOSIL®

as a function of atmospheric moisture at room temperature (Source:

Ref. [2]). |

|

Like all silicones, RTV-1

silicone elastomers (the cured rubbers) are highly resistant

to chemicals,

ozone and UV radiation (see also experiments "Influence

of ozone on silicone rubber compared with other types of rubber" and "Solubility

and chemical resistance of silicone rubber"). They are

also noted for their outstanding water repellency. However,

the properties

of silicone elastomers vary according to the crosslinking systems

employed, and this determines their suitability for specific

applications. |

|

| Alkaline

systems |

Neutral

systems |

Acidic

systems |

| |

No odor released

during curing |

|

| |

|

Good adhesion to glass,

ceramics, metals and plastics |

| Good adhesion to

building materials, glass, ceramics |

No corrosion of metals

or plastics |

|

| Readily compounded (applies

to amine systems) |

|

Excellent transparency

(applies to acetoxy system) |

| Good mechanical properties |

|

Good mechanical properties |

| Environmental stress

cracking of polycarbonates |

|

Environmental stress

cracking of polycarbonates |

|

| Table 3: Properties of various silicone

rubber elastomers made with different crosslinkers (Source:

Ref. [2]). |

|

The aforementioned properties,

simplicity of use and reliability, make RTV-1 silicone elastomers

excellent sealant and jointing materials for avoiding stress

cracking in masonry. This is caused by constant movement and

stresses that result from thermal fluctuations, moisture-related

causes, shrinkage of building materials, mechanical fluctuations

or subsidence of the substrate. These deleterious effects can

be avoided by bridging the movements with elastic joints. This

is especially true for combinations of different materials, such

as glass/metal or stone/metal, because each one has a different

coefficient of expansion.

RTV-1 silicone rubbers are therefore mostly used in the construction

industry and are probably the silicone products best known to

the general public, especially the products sold in cartridges.

Other application areas are to be found in the automotive, electrical,

electronics and textile industries, where they serve as seals,

bonded joints and coatings. |

|

6

References 6

References |

|

W. Held et al., Learning

by Doing – School Experiments with WACKER Products

(handbook accompanying WACKER's Experimental Kit), Wacker Chemie AG, Munich,

2007, p. 50-51 |

|

|