|

Chemical Resistance of Silicone Rubber

Compared With That of Other Elastomers |

|

1

Materials, Chemicals, Time Needed 1

Materials, Chemicals, Time Needed |

|

- Vials with snap-on lids

- Spring balance + press

- Tweezers

- Balance

- Various natural rubber specimens (shoe sole, rubber tube, natural

rubber)

- Various silicone rubber samples from WACKER's Experimental Kit,

e.g. HTV(b), HTV(s), HTV(w) and a self-made silicone elastomer RTV2(r)

- Acetone, F

- Gasoline (normal, unleaded), F

- Hydrochloric acid, c = 2 mol/l, hydrochloric acid, conc. C

- Sodium hydroxide, c = 2 mol/l, sodium hydroxide, conc.

w = 50 %, C

- Mineral oil (e.g. SAE 15 W 40), F

- Sulfuric acid, c = 1 mol/l, C

It is not possible to

state the precise duration for this experiment as the time needed

for sample preparation, analysis etc. will depend on the number

of pupils, samples and chemicals. |

|

2

Procedure and Observations 2

Procedure and Observations |

|

| Protective gloves and safety glasses must be worn when working

with these chemicals. |

|

|

| Sketch

of experiment: Chemical resistance of silicones |

|

|

First,

slice the various rubber samples into rectangles. Investigate

the tensile strength of the samples manually and with a tensile

force of 10 N. Determine the weight of each sample. First,

slice the various rubber samples into rectangles. Investigate

the tensile strength of the samples manually and with a tensile

force of 10 N. Determine the weight of each sample.

Place the elastomer samples in the different vials (or test

tubes), cover each one with a few milliliters of a different

chemical, put the lids on and leave for about one week.

Then remove each sample from the chemical, dry it and weigh

it again. Examine the samples for changes in appearance and

tensile strength.

Tabulate the observations and rate the chemical resistance

on a scale of 1-3.

1 = High resistance (no changes), 2 = Average resistance (slight

changes, e.g. color of solution has changed) and 3 = Low resistance

(material is extensively attacked or destroyed).

The following

observations were made after one week in a reference experiment:

Elastomer

+ acetone: Elastomer

+ acetone:

|

|

|

|

|

|

|

Weight in g |

Tear strength at 10 N |

|

|

| Sample |

Before |

After |

Before |

After |

Observation |

Chemical

resistance |

| Natural rubber |

/ |

/ |

Yes |

Yes |

Slightly swollen,

but no other visible changes. No change in elasticity or tear strength |

2 |

| Shoe sole |

0.2 |

0.25 |

Yes |

Yes |

Liquid slightly

yellow. No visible changes to sole.

No change in elasticity or tear strength |

2 |

| Rubber tubing |

0.45 |

0.5 |

Yes |

Yes |

Liquid slightly

yellow. No visible changes to tubing.

No change in elasticity or tear strength |

2 |

| HTV(b) |

0.3 |

0.3 |

Yes |

Yes |

No visible changes.

No change in elasticity or tear strength |

1 |

| HTV(s) |

0.3 |

0.35 |

Yes |

Yes |

No visible changes.

No change in elasticity or tear strength |

1 |

| HTV(w) |

0.55 |

0.37 |

Yes |

Yes |

No visible changes.

No change in elasticity or tear strength |

1 |

| RTV2(r) |

0.55 |

0.65 |

Yes |

Yes |

No visible changes.

No change in elasticity or tear strength |

1 |

|

|

| (Due to the low mass of the natural rubber samples,

they were not weighed.) |

|

|

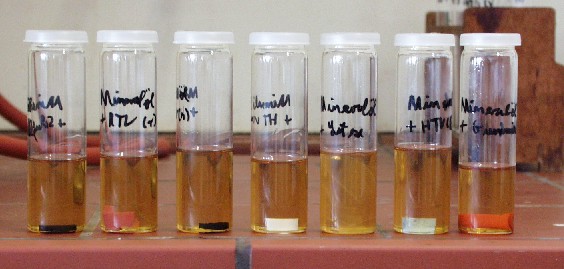

Photo

1: Elastomer samples after one week in acetone Photo

1: Elastomer samples after one week in acetone |

|

Elastomer

+ gasoline: Elastomer

+ gasoline: |

|

|

|

|

|

|

Weight in g |

Tear strength at 10 N |

|

|

| Sample |

Before |

After |

Before |

After |

Observation |

Chemical

resistance |

| Natural rubber |

/ |

/ |

Yes |

No |

No outer changes.

Sharp drop in elasticity and tear strength. |

3 |

| Shoe sole |

0.2 |

0.3 |

Yes |

No |

Sample slightly swollen.

Sharp drop in elasticity and tear strength. |

3 |

| Rubber tubing |

0.5 |

1.05 |

Yes |

No |

Sample very swollen.

Sharp drop in elasticity and tear strength. |

3 |

| HTV(b) |

0.4 |

0.7 |

Yes |

Yes |

Sample moderately swollen.

No change in elasticity or tear strength. |

2 |

| HTV(s) |

0.5 |

0.85 |

Yes |

Yes |

Sample moderately swollen.

No change in elasticity or tear strength. |

2 |

| HTV(w) |

0.2 |

2 |

Yes |

No |

Sample extensively swollen.

Sharp drop in elasticity and tear strength. |

3 |

| RTV2(r) |

0.2 |

0.77 |

Yes |

No |

Sample extensively

swollen.

Sharp drop in elasticity and tear strength.

|

3 |

|

|

|

Photo

2: Elastomer samples after one week in gasoline Photo

2: Elastomer samples after one week in gasoline |

|

Elastomer

+ hydrochloric acid, c = 2 mol/l: Elastomer

+ hydrochloric acid, c = 2 mol/l: |

|

|

|

|

|

|

Weight in g |

Tear strength at 10 N |

|

|

| Sample |

Before |

After |

Before |

After |

Observation |

Chemical

resistance |

| Natural rubber |

/ |

/ |

Yes |

Yes |

Slight yellow discoloration of sample.

No change in elasticity or tear strength |

2 |

| Shoe sole |

0.3 |

0.3 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| Rubber tubing |

0.35 |

0.4 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(b) |

0.45 |

0.5 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(s) |

0.3 |

0.3 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(w) |

0.3 |

0.3 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| RTV2(r) |

0.4 |

0.4 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

|

|

Elastomer

+ hydrochloric acid, c = 10 mol/l (HCl conc.): Elastomer

+ hydrochloric acid, c = 10 mol/l (HCl conc.): |

|

|

|

|

|

|

Weight in g |

Tear strength at 10 N |

|

|

| Sample |

Before |

After |

Before |

After |

Observation |

Chemical

resistance |

| Natural rubber |

/ |

/ |

Yes |

Yes |

Sample turned

white. No change in elasticity or tear strength |

2 |

| Shoe sole |

0.25 |

0.27 |

Yes |

Yes |

Solution turned

deep yellow.

Sample feels somewhat harder.

No change in elasticity or tear strength

|

2 |

| Rubber tubing |

0.25 |

0.3 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(b) |

0.45 |

Not measurable |

Yes |

No |

Solution turned

slightly yellow.

Sample itself turned deep blue and crumbles on removal and when handled.

No longer elastic or tear resistant |

3 |

| HTV(s) |

0.3 |

0.25 |

Yes |

Yes |

No visible changes.

No change in elasticity or tear strength

|

1 |

| HTV(w) |

0.3 |

0.3 |

Yes |

Yes |

Sample slightly tacky; no visible changes otherwise.

Sample tears somewhat faster, but passes the test. |

2 |

| RTV2(r) |

0.6 |

0.7 |

Yes |

No |

Sample turned yellow and is very tacky and greasy.

Solution also turned yellowish.

Sample no longer elastic and snaps when pulled. |

3 |

|

|

|

Photo

3: Elastomer samples after one week in concentrated hydrochloric

acid Photo

3: Elastomer samples after one week in concentrated hydrochloric

acid |

|

Elastomer

+ sodium hydroxide, c = 2 mol/l: Elastomer

+ sodium hydroxide, c = 2 mol/l: |

|

|

|

|

|

|

Weight in g |

Tear strength at 10 N |

|

|

| Sample |

Before |

After |

Before |

After |

Observation |

Chemical

resistance |

| Natural rubber |

/ |

/ |

Yes |

Yes |

Sample no longer as transparent; no other changes discernible.

No change in elasticity or tear strength |

1 |

| Shoe sole |

0.2 |

0.2 |

Yes |

Yes |

Sample somewhat softer and solution has turned yellow.

Slight increase in elasticity. No change in tear strength. |

2 |

| Rubber tubing |

0.35 |

0.48 |

Yes |

Yes |

Sample feels somewhat softer.

Liquid has turned deep yellow-orange.

Elastic, but not as tear resistant |

2 |

| HTV(b) |

0.35 |

0.35 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(s) |

0.25 |

0.25 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(w) |

0.3 |

0.3 |

Yes |

Yes |

Sample slightly tacky; no visible changes otherwise.

No change in elasticity or tear strength |

1 |

| RTV2(r) |

0.27 |

0.28 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

|

|

Elastomer

+ sodium hydroxide, w = 50 %: Elastomer

+ sodium hydroxide, w = 50 %: |

|

|

|

|

|

|

Weight in g |

Tear strength at 10 N |

|

|

| Sample |

Before |

After |

Before |

After |

Observation |

Chemical

resistance |

| Natural rubber |

/ |

/ |

Yes |

Yes |

Sample no longer as transparent; no other changes discernible.

No change in elasticity or tear strength |

1 |

| Shoe sole |

0.2 |

0.25 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| Rubber tubing |

0.922 |

0.908 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(b) |

0.223 |

0.192 |

Yes |

Yes |

Surface of sample is dark blue, crumbly and soapy. No change beneath surface

Elastic and tear resistant |

3 |

| HTV(s) |

0.682 |

0.695 |

Yes |

Too soapy to measure |

Surface of sample is tacky and soapy.

No change beneath surface.

Elastic and tear resistant |

3 |

| HTV(w) |

0.677 |

0.697 |

Yes |

Too soapy to measure |

Surface of sample is tacky and soapy.

No change beneath surface.

Elastic and tear resistant |

3 |

| RTV2(r) |

0.645 |

0.639 |

Yes |

Yes |

Somewhat soapy; no changes otherwise. No change in elasticity or tear strength |

2 |

|

|

Elastomer

+ mineral oil SAE 15 W 40: Elastomer

+ mineral oil SAE 15 W 40: |

|

|

|

|

|

|

Weight in g |

Tear strength at 10 N |

|

|

| Sample |

Before |

After |

Before |

After |

Observation |

Chemical

resistance |

| Natural rubber |

/ |

/ |

Yes |

No |

Sample slightly swollen; no other changes discernible.

Elasticity almost zero

Sharp drop in tear strength |

3 |

| Shoe sole |

0.25 |

0.28 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| Rubber tubing |

0.3 |

0.43 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(b) |

0.3 |

0.303 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(s) |

0.27 |

0.276 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(w) |

0.25 |

0.246 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| RTV2(r) |

0.6 |

0.613 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

|

|

|

Photo

4: Elastomer sample after one week in mineral oil SAE 15 W 40 Photo

4: Elastomer sample after one week in mineral oil SAE 15 W 40 |

|

Elastomer

+ sulfuric acid, c = 1 mol/l: Elastomer

+ sulfuric acid, c = 1 mol/l: |

|

|

|

|

|

|

Weight in g |

Tear strength at 10 N |

|

|

| Sample |

Before |

After |

Before |

After |

Observation |

Chemical

resistance |

| Natural rubber |

/ |

/ |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| Shoe sole |

0.2 |

0.246 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| Rubber tubing |

0.2 |

0.249 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(b) |

0.5 |

0.42 |

Yes |

Yes |

Sample has turned somewhat darker; no other changes discernible.. No change in elasticity or tear strength |

1 |

| HTV(s) |

0.2 |

0.235 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| HTV(w) |

0.25 |

0.255 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

| RTV2(r) |

0.6 |

0.637 |

Yes |

Yes |

No visible changes. No change in elasticity or tear strength |

1 |

|

|

3

Discussion of Results 3

Discussion of Results

|

|

| The observations for the chemical resistance of

the elastomers investigated at room temperature may be tabulated

as follows: |

|

| |

Natural rubber |

Shoe sole |

Rubber tubing |

HTV(b) |

HTV(s) |

HTV(w) |

RTV2(r) |

| Acetone |

1 |

2 |

2 |

1 |

1 |

1 |

1 |

| Gasoline |

3 |

3 |

3 |

2 |

2 |

3 |

3 |

| Hydrochloric

acid 2 mol/l |

2 |

1 |

1 |

1 |

1 |

1 |

1 |

| Hydrochloric

acid 10 mol/l |

2 |

2 |

1 |

3 |

1 |

2 |

3 |

| Sodium

hydroxide 2 mol/l |

1 |

2 |

2 |

1 |

1 |

1 |

1 |

| Sodium

hydroxide 50 % |

1 |

1 |

1 |

3 |

3 |

3 |

2 |

| Mineral

oil |

3 |

1 |

1 |

1 |

1 |

1 |

1 |

| Sulfuric

acid 1 mol/l |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

|

Comparison

of the chemical resistances shows that silicones are resistant

to mineral oil, acetone, and fairly dilute solutions (c < 2

mol/l) of inorganic acids and bases. They are attacked by concentrated

solutions of strong acids and bases, and by gasoline. Comparison

of the chemical resistances shows that silicones are resistant

to mineral oil, acetone, and fairly dilute solutions (c < 2

mol/l) of inorganic acids and bases. They are attacked by concentrated

solutions of strong acids and bases, and by gasoline.

The observed discrepancies among the silicones investigated are

due to different additives and degrees of crosslinking.

The observed behavior of the silicones toward acids and bases

can be explained in terms of the chemical structure of their

molecules. Due to the polarity of the siloxane linkage Si-O,

the negatively charged oxygen atom could undergo electrophilic

attack, while the positively charged silicon atom could undergo

nucleophilic attack.

This means that the following reactions are theoretically possible

for the degradation of silicones by inorganic acids and bases

(the curved arrows in the equations indicate the movement of

electron pairs):

|

|

|

Depolymerization

of silicones by hydroxide ions Depolymerization

of silicones by hydroxide ions |

|

|

Depolymerization

of silicones by inorganic acids HX Depolymerization

of silicones by inorganic acids HX |

|

However,

high concentrations of hydronium or hydroxide ions, i.e. concentrated

solutions of strong acids and bases, are needed before these

reactions will proceed. This explains why silicones are stable

to dilute solutions of inorganic acids and bases. However,

high concentrations of hydronium or hydroxide ions, i.e. concentrated

solutions of strong acids and bases, are needed before these

reactions will proceed. This explains why silicones are stable

to dilute solutions of inorganic acids and bases.

The action of gasoline on silicones is not a chemical reaction.

Instead, physical processes are at work. The swelling of the

silicones in gasoline is due to the fact that nonpolar molecules

penetrate from the gasoline into the macromolecular silicone

material and accumulate in the molecular network.

The organic elastomers studied show moderate to very good resistance

to acids and alkalies. But, they are attacked by organic substances,

such as engine oil, gasoline and acetone (which cause swelling

or dissolution).

The resistance of the organic elastomers to acids and bases can

be explained in terms of their particle structure.

Organic elastomers generally are built up from unsaturated polymers.

Natural rubber consists of cis-1,4-polyisoprene macromolecules

(see diagram) that become linked to each other via sulfur atoms

during vulcanization.

|

| Fig.: cis-1,4-Polyisoprene (natural

rubber) Source: Thieme Computerlexikon |

|

The

primary points of attack by reagents in polyisoprene molecules

are the carbon-carbon double bonds. These, however, are stable

to direct nucleophilic attack by, e.g. hydroxyl ions. On the

other hand, hydronium ions from acidic solutions can attack

the carbon-carbon double bonds by electrophilic addition. This

explains why the examined organic elastomers were found to

be more resistant in concentrated sodium hydroxide than in

concentrated hydrochloric acid. The

primary points of attack by reagents in polyisoprene molecules

are the carbon-carbon double bonds. These, however, are stable

to direct nucleophilic attack by, e.g. hydroxyl ions. On the

other hand, hydronium ions from acidic solutions can attack

the carbon-carbon double bonds by electrophilic addition. This

explains why the examined organic elastomers were found to

be more resistant in concentrated sodium hydroxide than in

concentrated hydrochloric acid.

The fact that the organic elastomers, which essentially consist

of nonpolar molecules, gradually swell up and dissolve in organic

solvents such as gasoline, acetone and engine oil is due to

interactions between the molecules of the solvents and the

molecules of the organic elastomers (Like dissolves Like).

These interactions are primarily Van der Waals forces.

|

|

4

Tips and Comments 4

Tips and Comments

|

|

- As an alternative to this test, the chemical

resistance of the elastomer samples was studied by exposing

them to gasoline,

concentrated hydrochloric acid, c = 10 mol/l, sodium hydroxide,

w = 50% and acetone at 45°C. The elastomer samples were

placed along with the respective liquid in a round-bottom flask,

which

was then sealed and heated for roughly one hour at approx.

45 °C.

The results for conc. hydrochloric acid and gasoline were

the same as those observed in the long-term test. No changes

were

observed, however, in the case of either conc. sodium hydroxide

or acetone. Quite likely, the reason for this is that the

reaction rate and the diffusion rate were too low. The

exposure period

was therefore not long enough for a visible change to occur.

- A

further addition to the test was to examine all samples

under a microscope (magnification: x100) before and after exposure

to the liquids. No microscopic changes were observed,

however,

in any of the examined samples. For time reasons, microscopic

examination of the samples should not be performed in

class.

This experiment teaches the pupils how to determine the

chemical resistance of elastomers and other polymers

to different

liquids. It enables them to choose the best polymer for

every application.

For example, there would be little point in using seals

made from natural rubber in a gasoline pipe.

- As for silicones, the

pupils learn how silicones react to different chemicals,

especially inorganic acids and bases. Here, again,

they learn the didactically important relationship between

substance property and particle structure.

- Since the experiment is relatively

safe if the safety advice is followed (wear gloves, safety

glasses), it makes a good classroom

experiment. It is advisable to let the pupils work in

groups to save time and to encourage communication. Each group

should

examine the behavior of the samples in one liquid. The

samples should be prepared at the beginning or the end of a

class

to prevent valuable teaching time from being wasted. The

results could then be discussed the following week.

|

|

5

Supplementary Information 5

Supplementary Information

|

|

The chemical resistance of

polymer materials, such as natural rubber and silicone rubber,

can be

divided into two groups according to the form of exposure.

- Physically active media do not react with macromolecular

material, but they

will contribute to swelling to the point of dissolution,

thereby causing reversible changes to the material’s

properties.

The underlying mechanism of physically active media is based

on the destruction of the molecular bonds between the macromolecules.

Chemically inert hydrocarbons and some of their derivatives

are examples of such liquids.

Physically active media may cause leaching of additives (e.g.

plasticizers) from plastics and elastomers, as a result of

which the properties of the material are irreversibly damaged.

The reaction of a macromolecular material to physically active

media can be estimated from the polarity of each reagent.

Generally, materials made from nonpolar molecules will swell

up and dissolve

in nonpolar solvents whereas they will be physically resistant

to polar compounds. Macromolecules containing polar groups

will either be soluble in polar solvents or will swell up,

whereas

they will be resistant to nonpolar compounds.

The resistance of macromolecular materials to physically

active liquids is dependent on other factors, especially

the degree

of crosslinking between the macromolecules. Swelling in solvents

decreases with increasing crosslinkage. Thus, ebonite swells

much less than soft rubber in hydrocarbons.

Fillers can also influence the resistance of polymers to

physically active media.

- Chemically active media react with

the macromolecular material and change its properties

irreversibly. Chemical degradation

of macromolecules is typified by the fact that minor

chemical changes are enough to cause very distinctive changes

in

physical properties.

Macromolecular substances obey the same laws as low-molecular

substances during chemical reactions. The course of

the reaction, however, is different for macromolecular

and

low-molecular

substances.

As a rule, the reaction between the aggressive chemical

and the macromolecular material takes place in a heterogeneous

system

(solid/liquid or solid/gas), which is why the course

of the

reaction, just like swelling and dissolution, is heavily

influenced by

diffusion. The consequence in some chemical reactions

is that a film of reaction products forms between the

macromolecular

material and the aggressive medium to impede diffusion

of the

medium and therefore reduce the degradation rate. Such

protective surface coatings explain the high chemical

resistance of

natural rubber to hydrochloric acid and sulfuric acid.

Furthermore, the resistance of macromolecular materials

to chemically active substances is influenced over

wide limits

both positively

and negatively by fillers and other additives.

The crosslinking density also has an influence on the

chemical resistance.

|

|

6

References 6

References |

|

- M. Tausch, M. von Wachtendonk (editors), CHEMIE S II, STOFF-FORMEL-UMWELT,

C.C. Buchner, Bamberg (1993), (1998), S. 337 - 352

- M. Tausch, M. von Wachtendonk (editors), STOFF-CHEMIE S

I, FORMEL-UMWELT, C.C. Buchner, Bamberg (1996), (1997), S.

228 - 233

- M. Tausch, M. von Wachtendonk (editors), CHEMIE 2000+,

C.C. Buchner, Bamberg (2001), S. 60 - 67

|

|

|