1. Experiment is contained in the WACKER's Experimental Kit. |

No |

2. Experimental procedure has been modified |

/ |

3. A separate experimental procedure has been devised |

No |

4. Video clip available |

No |

5. Flash animation available |

No |

6. Other materials: "Ozone" on

the Wuppertal University “Didactics” homepage |

|

Influence of Ozone on Silicone Rubber

and Other Types of Rubber |

|

1

Materials, Chemicals, Time Needed 1

Materials, Chemicals, Time Needed |

|

- Ozone apparatus with UV lamp, available,

for example, from Hedinger, Stuttgart

- Aluminum foil

- Glass tube

- Glass rod

- 2 stoppers

- Wash bottle

- Spring balance

- Press

- Microscope

- Scotch tape

- Carpet knife

- Various rubber samples (bicycle inner tube, rubber tubing,

natural rubber)

- Various silicone rubber specimens from WACKER's Experimental Kit, e.g. HTV

- Oxygen, O

- Sulfuric acid, conc., C

Allow about 10 minutes to set up the apparatus.

It takes about 20 minutes to conduct the experiment, including

examining the specimens under the microscope. |

|

2

Procedure and Observations 2

Procedure and Observations |

|

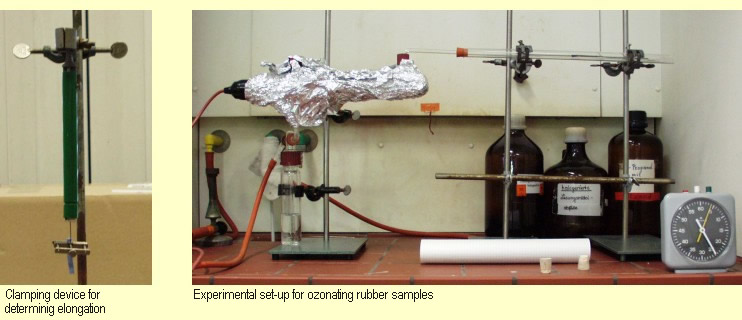

| First, set up the apparatus (see diagram). |

|

As

ozone will be used, conduct the experiment in a fume cupboard. As

ozone will be used, conduct the experiment in a fume cupboard.

Cover the ozone reactor with aluminum foil (protects against

UV radiation; see photo below).

Cut various rubber specimens into long rectangles of uniform

thickness and about 0.5 cm in width.

Clamp each rubber specimen lengthwise, ensuring it is held

adequately in the retort (see photo), and measure the elongation

under a force of 10 N.

Use Scotch tape to attach the specimen under the same elongation,

i.e. under a force of 10 N, to the glass rod and then place

this assembly face up in the glass tube (see diagram above).

Generate the ozone by first flushing the entire apparatus with

dry oxygen (see diagram above) for about 2 minutes. Then switch

on the the UV lamp and slowly (roughly 1 bubble per second)

pass the mixture of oxygen and ozone generated in the UV reactor

over the rubber specimen inside the glass tube. Continue the

ozone treatment for 15 minutes. Examine the specimen for macroscopic,

microscopic and mechanical changes.

It is important to ozonate all the specimens under the same

conditions in order that their resistance to ozone may be compared.

|

|

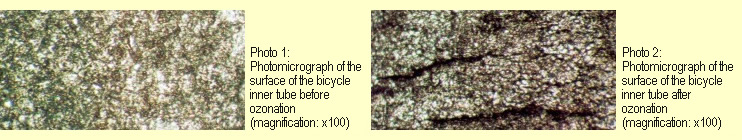

The following reproducible observations

were made in reference experiments under an elongation of 10

N:

Bicycle

inner tube (force = 10 N, width = approx. 0.5 cm) Bicycle

inner tube (force = 10 N, width = approx. 0.5 cm)

Even as the ozone was being fed in, small cracks formed initially

in the surface of the specimen perpendicular to the acting force.

The cracks gradually grew until the rubber tore completely after

about 10 minutes.

A check of the mechanical properties revealed an extensive decline in tear strength

and elasticity.

Examination under the microscope after ozonation revealed small black veins (see

photos 1 and 2).

|

|

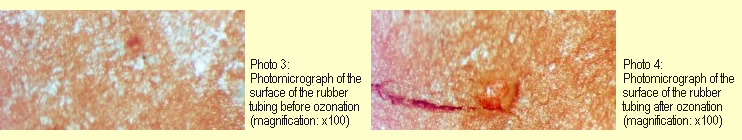

Rubber

tubing (force = 10 N, width = approx. 0.5 cm) Rubber

tubing (force = 10 N, width = approx. 0.5 cm)

As with the bicycle inner tube, small cracks appeared first in the red

rubber tubing (laboratory tubing) and grew until the specimen eventually

tore after about 7 minutes.

Again, there was an extensive reduction in mechanical properties (tear

strength and elasticity).

After ozonation, red veins were seen under the microscope (see photos 3

and 4). |

|

Natural

rubber: (force = 1 N, width = approx. 0.5 cm) Natural

rubber: (force = 1 N, width = approx. 0.5 cm)

The natural rubber specimen was only stretched under a tensile force of

1 N, as otherwise it would have become too long.

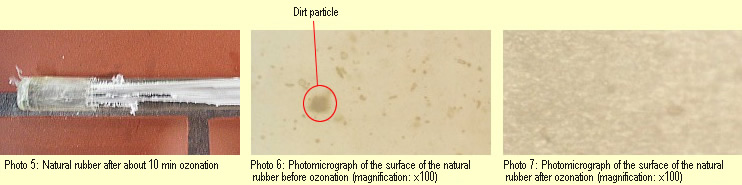

During ozonation, the specimen turned white or lost its transparency. Fringes

formed at the edge of the specimen. Small holes and cracks formed in the

center (see photo 5). After 10 to 15 minutes, the specimen tore at one

point.

Those areas of the specimen that lost their transparency were no longer

as elastic and tore faster.

Examination under the microscope after ozonation revealed small black dots

that were absent beforehand (see photos 6 and 7). |

|

Silicone

rubber HTV(b): (force = 10 N, width = approx. 0.5 cm) Silicone

rubber HTV(b): (force = 10 N, width = approx. 0.5 cm)

Ozonation failed to produce any macroscopic (see photo 8), microscopic

or mechanical changes in the HTV(b) silicone rubber specimen from

WACKER's Experimental Kit. |

|

| Unfortunately, photographs could

not be taken under the reflected-light microscope as a sharp

image of the specimen could not be obtained. The specimen was

too thick for a transmitted-light microscope.

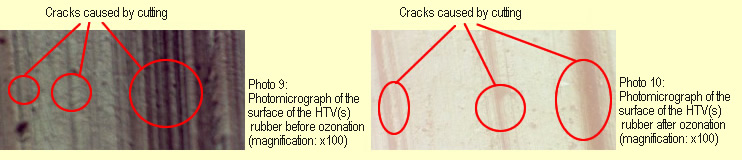

Silicone

rubber HTV(s): (force = 10 N, width = approx. 0.5 cm) Silicone

rubber HTV(s): (force = 10 N, width = approx. 0.5 cm)

Again, no macroscopic, microscopic (see photos 9 and 10) or mechanical

changes were observed.

|

|

| The differences in the appearance

of the photomicrographs are caused by different light intensities

when the photographs were taken. The clearly visible parallel

lines were caused by the carpet knife during cutting and not

by ozonation.

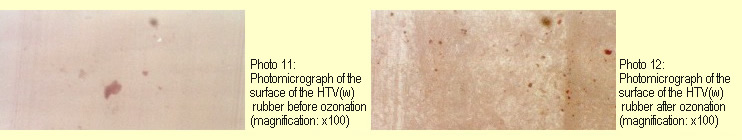

Silicone

rubber HTV(w): (force = 10 N, width = 0.5 cm) Silicone

rubber HTV(w): (force = 10 N, width = 0.5 cm)

No macroscopic or mechanical changes were observed either before or

after ozonation.

As with silicone HTV(s), the slight differences in the photomicrographs

(see photos 11 and 12) may be explained in terms of differences in

light intensity during photography and the different structures created

by cutting. They are not due to ozonation.

|

|

|

3

Discussion of Results 3

Discussion of Results

|

|

From the observations above, it may be said that “silicone

rubber” (more accurately: the silicone rubbers from

WACKER's Experimental Kit) is not attacked by ozone under the conditions

of the experiment.

In contrast, “normal rubber” of the kind used in

rubber tubing (laboratory tubing), bicycle inner tubes and

natural rubber, is extensively attacked by ozone and is destroyed.

The order of ozone resistance is therefore as follows:

The “normal types of rubber” are attacked much

more extensively than the silicones because they are made

from polymers that contain carbon=carbon double bonds (C=C).

These

react with ozone (see below).

Silicone polymer molecules generally do not contain any carbon=carbon

double bonds and thus cannot be attacked by ozone. For example,

a 2 % content of ozone in the atmosphere will not bring about

any changes in the properties of silicone rubber, not even

for 70 hours exposure at 40 °C. Given natural

aging processes, silicone rubber is virtually totally resistant

to

oxygen and ozone.

The

specimens in the experimental apparatus were exposed to ozone

concentrations that are much higher than occur naturally

(compare the ozone content of air in 5 Supplementary

information). The

specimens in the experimental apparatus were exposed to ozone

concentrations that are much higher than occur naturally

(compare the ozone content of air in 5 Supplementary

information).

Despite its low concentration at the earth’s surface, ozone does still

play an important role in the atmospheric aging of plastics and elastomers. Ozone

causes aging in two different ways.

In saturated polymers, it initiates oxidation.

The free radicals formed at the start of the reaction then participate in further

reactions.

|

|

|

| Ozone plays a much more important role

in the degradation of polymers containing C=C double bonds

of the kind found in conventional rubber. Rubber is natural

rubber latex (cis-1,4-polyisoprene) that has been vulcanized

with sulfur. |

|

|

When

ozone reacts with unsaturated compounds, the molecules are cleaved

at the C=C double bonds. For this reason, the reaction is also

called ozonolysis. Ozonolysis leads to oxidative degradation

of alkenes to carbonyl compounds, whose molecules contain fragments

of the alkene molecule. When

ozone reacts with unsaturated compounds, the molecules are cleaved

at the C=C double bonds. For this reason, the reaction is also

called ozonolysis. Ozonolysis leads to oxidative degradation

of alkenes to carbonyl compounds, whose molecules contain fragments

of the alkene molecule.

The mechanism of ozonolysis involves electrophilic addition of

the ozone across the double bond. This transformation yields

the primary ozonide. The primary ozonide is unstable and fragments

into a carbonyl compound and a carbonyl oxide. Further reactions

then follow. |

|

| In the case of unsaturated polymers, such

as natural rubber (cis-1,4-polyisoprene), ozonolysis destroys

the polymer chains and thus changes the properties of the material.

The extent to which ozone affects unsaturated polymers, especially

natural rubber, depends on whether or not the polymers are being

subjected to mechanical stress at the same time. In the absence

of such stress (e.g. stretching and relaxation of a piece of

rubber), an ozonated layer builds up on the surface of the rubber,

forming a kind of protective barrier that prevents more ozone

from penetrating into the compound.

Mechanical

stress (e.g. stretching or elongation) leads to the formation of typical

ozone cracks, with the cracks always occurring perpendicular to the acting

force. Mechanical

stress (e.g. stretching or elongation) leads to the formation of typical

ozone cracks, with the cracks always occurring perpendicular to the acting

force.

One possible explanation for the accelerating effect of mechanical stress

on the degradation of elastomers by ozone is that the deformation mechanically

destroys the ozonated surface layer. This exposes fresh surfaces and facilitates

further reactions between the ozone and the elastomer.

Crack formation is a serious type of damage because, if the cracks grow as

degradation is happening, the product concerned may be totally destroyed.

Ozone cracking depends both on the composition of the rubber and on the mechanical

stress, ozone concentration and the temperature.

Ozone-induced changes in the polymer chain of the elastomer manifest

themselves as a reduction in tensile strength, extensibility and structural

strength. Furthermore, the oxidation generates functional groups containing

oxygen that reduce the mobility of the polymer chains and thereby impair

the material’s dynamic properties.

|

|

4

Tips and Comments 4

Tips and Comments

|

|

- Since the tensile stress acting

on the specimens varies with the width and thickness of

the specimens, quantitative comparison is not possible. Simple

tools (e.g. carpet

knife) are unable to cut the specimens uniformly.

- The length of

time needed for the specimens to tear fluctuates in accordance

with the tensile stress, the ozone concentration,

the temperature and the degree of crosslinking.

- Except for

the temperature and possible tensile stress, these measuring

parameters cannot be kept constant. However, as

the observations show, this has no effect on the qualitative

results.

If the tensile stress is too low, the specimens show

no reaction.

- Since no changes were observed in the silicone specimens

at 10 N, the experiment was repeated on these specimens

by stretching

them as far as possible by hand. However, there were

no observable changes. Additionally, the silicones were placed

in an ozone

atmosphere (tube was sealed with Scotch tape) for longer

than a day. Again, there were no changes.

- The experiment

has a fairly high bearing on everyday life, because resistance

to ozone affects the scope for using

the elastomers

concerned and is thus regularly checked in industry.

- The

experiment can serve to familiarize the pupils with an

important property, namely the great difference between

the

resistance

of silicone rubber and other natural and synthetic

elastomers to ozone.

- This difference in materials can be graphically

illustrated at the particle level on the basis of the structural

feature of

the “C=C double bond”, even if the

mechanism of ozonolysis itself is not discussed.

It is enough

to restrict

the classroom

lesson to the overall reaction involved in ozonolysis.

|

|

5

Supplementary Information 5

Supplementary Information

|

|

Ozone O3 is formed in the ozonosphere at a height

of 20 to 60 km above the earth’s surface by the following

photochemical reaction of oxygen at wavelengths less than 242

nm.

M represents a collision partner, e.g. a nitrogen or oxygen molecule,

which is needed to absorb the energy released.

Ozone formation is counteracted mainly by photolysis at longer wavelengths

to maintain a photostationary equilibrium between oxygen and ozone in

the ozonosphere.

The constant turbulence present causes some ozone to be transported by

airstreams down as far as the earth’s surface. Some of the ozone

in the lower layers of the atmosphere is also formed by electrical discharges

(lightning) and some ozone close to the ground is formed as photochemical

smog when intense sunlight acts on airborne impurities (vehicle exhaust

fumes).

Nevertheless, the average concentration of ozone at the earth’s

surface is very low. It varies from 0.02 ppm to 0.05 ppm as a function

of the season, the location of the measuring point and the meterological

conditions.

Further information (in German) on the subject of ozone may be found

under http://www.chemiedidaktik.uni-wuppertal.de/ > Unterrichtsmaterial > Ozon. |

|

6

References 6

References |

|

- M. Tausch, M. von Wachtendonk (editors), CHEMIE S II, STOFF-FORMEL-UMWELT,

C.C. Buchner, Bamberg (1993), (1998), S. 226 f., S. 384 f

- M. Tausch, M. von Wachtendonk (editors), STOFF-CHEMIE S

I, FORMEL-UMWELT, C.C. Buchner, Bamberg (1996), (1997), S.

58 f

- M. Tausch, M. von Wachtendonk (editors), CHEMIE 2000+,

C.C. Buchner, Bamberg (2001), S. 78 f

|

|

|

|