|

Silicone-Coated Paper

1

Materials, Chemicals, Time Needed 1

Materials, Chemicals, Time Needed

- Wooden board

- Paper

- Glass rod

- Drying cupboard or hot plate

- Scotch tape

(or other adhesive tape)

- Glass beaker, 100 ml

- DEHESIVE® 920, Xi, F, N

- WACKER Crosslinker V24, Xi, F, N

- WACKER Catalyst

OL, Xi

(See Part

5 Supplementary Information and References for details about abbreviations)

Allow around 45 minutes to prepare the DEHESIVE® mixture

and to coat the paper. The curing time depends on the temperature

and the coating thickness. However, it should be around 30

minutes max. at the temperature of the experiment. The experiment

can therefore be performed during a double lesson.

2

Procedure and Observations 2

Procedure and Observations

Add 1.3 g Crosslinker V24 (clear liquid)

to 50 g DEHESIVE® (clear liquid) and stir both

liquids with a glass rod. Add 0.5 g of Catalyst OL (yellowish

liquid) and then stir again vigorously. Coat the papers as

follows: |

|

- Tape

the paper to the wooden board or other flat, solid washable

surface.

- Apply a bead of the reaction mixture to one end

of the sheet.

- Use

the glass rod to spread the mixture over the paper. Do

this by pressing the rod firmly onto the paper and drawing

it downward

(see photo, right).

- Then place the coated paper in the drying

cupboard at approx. 130 °C and measure how much time

elapses until curing is finished. When curing is finished,

the paper

will no longer be

tacky. Repeat the experiment to determine the curing time

at 50 °C and 100 °C.

- Finally, test the adhesive strength

of Scotch tape on the coated and uncoated paper.

When the reaction mixture is being prepared,

a clear, readily flowing liquid is formed (right) that is easy

to spread over the paper to be coated.

It cures in the drying cupboard to form a clear, smooth, glaze-like

coating on the paper.

|

|

DEHESIVE® mixture |

|

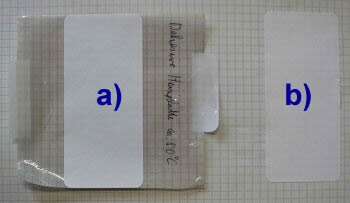

The following

observations may be made when comparing the adhesion of

strips of tape to coated and uncoated paper:

When the tape is removed from the untreated paper, the

paper is damaged. The tape has lost its tacky properties

and has become useless.

In contrast, the tape attached to the coated paper can,

just like sticky labels, be removed easily and without

damage, and can be reused (see photos below).

|

|

|

| |

Paper coated with DEHESIVE® |

|

|

|

|

| Strips of tape attached to siliconized

(a) and non-siliconized (b) paper |

|

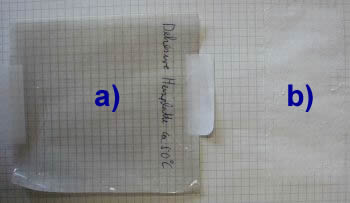

Siliconized (a) and non-siliconized (b)

paper after the strips have been removed |

|

|

The experiment to investigate the rate of

curing as a function of temperature shows that the curing time

depends heavily on the coating thickness and decreases with

increasing temperature. In several reference experiments, mean

curing times were measured as a function of the thickness of

the silicone coating and the temperature (see Table 1). |

|

| Temperature

in °C |

Curing

time in minutes |

130 |

Approx. 1 |

100 |

Approx. 3 |

50 |

Approx. 20 |

|

| Table 1: Curing times

at different temperatueres |

|

3

Discussion of Results 3

Discussion of Results

The DEHESIVE® 920

silicone rubber used in the experiment consists of polydimethylsiloxane

molecules that have crosslinkable vinyl groups. These undergo

addition curing (see Part 5 Supplementary Information) to form

a strongly adhering layer of silicone rubber consisting of

DEHESIVE® 920 on the treated paper. The methyl groups

of the silicone molecules align themselves such that they are

pointing away from the surface. Adhesion between the strip

of tape and the siliconized paper surface is relatively weak

because the intermolecular forces bonding the aligned silicone

molecules on the paper to the molecules of the adhesive are

fairly weak. The strip of tape can be readily removed from

the surface, without loss of adhesion.

In contrast, strong interactions occur between the cellulose

molecules of the untreated paper surface and the molecules

of adhesive. Once the strip of tape has been removed, it cannot

be reused and the paper itself is damaged.

The rate of the addition-curing reaction is increased by raising

the temperature. The curing time therefore falls as the temperature

rises. |

|

4

Tips and Comments 4

Tips and Comments

- It is best to weigh out and prepare the mixture

in a glass beaker because the catalyst and crosslinking

agent are viscous. If they were transferred separately to

the beaker,

the amount transferred would not be the same as the amount

weighed out.

- Before heating, remove the paper from the wooden

surface as otherwise the curing time will be much longer.

The reason is

that the wood does not heat up as quickly as the paper

and tends to have a cooling effect.

- The curing time varies with

the layer thickness. Therefore, ensure that layers of

similar thickness are applied to the

paper. The temperature-dependence of the curing rate

can be readily observed despite different layer thicknesses.

However,

the curing times are less reproducible.

- If a drying cupboard

is not available, heat the pieces of paper on standard

hot plates. The results will be less accurate

because

the temperature cannot be set so precisely. The curing

times will also be different from those in the drying cupboard.

Nevertheless, the dependence of the curing time on the

temperature

is readily

observed. Several reference trials conducted at 50 °C

and 100 °C yielded the curing times shown in Table

2.

|

|

Temperature in °C |

Curing time in minutes |

Approx. 100 |

Approx. 1 |

Approx. 50 |

Approx. 15 |

|

| Table 2: Curing times

as measured with an electric hot plate |

|

5

Supplementary Information 5

Supplementary Information

DEHESIVE® silicone release

papers are widely used to cover and protect the adhesive on

sticky labels so that they will stick where they are supposed

to. In the experiment described, just as in practice, both

solvent-based and solventless addition-curing or condensation-curing

polydimethylsiloxanes (silicone rubber) are used for coating

purposes. These cure very quickly at temperatures of 100 – 200 °C.

Release papers generally are constructed as follows: |

|

|

| Fig. 1. Structure of

a pressure-sensitive adhesive with a silicone coating (Source:

Ref. [11], p. 40) |

|

| The application areas of silicone release

papers are shown below: |

|

| Fig. 2. Use of silicone

release papers (Source:

Ref. [11], p. 40) |

|

To produce a very flexible, individual consistency

for different coatings, the DEHESIVE®- silicone

coating used in the experiment is generally processed in the

form of a 3-component material in practice.

These components

are:

- Polymer (DEHESIVE®):

Solvent-based and solventless polydimethylsiloxanes whose

end groups consist of crosslinkable hydroxyl or vinyl groups.

- Crosslinker: hydrogen polysiloxanes

with a high content of reactive Si-H groups for thermal hardening

of addition-curing systems. The nature and quantity of the

crosslinker determines the rub-off resistance and adhesive

strength of the silicone film.

- Catalyst: platinum

complexes (0.1 %, 1,000 ppm) for thermal curing of silicones.

The quantity of catalyst employed determines the production

rate, the curing temperature and the pot life (the maximum

length of time during which the mixture can still be used).

|

|

| The following reactions occur according

to the type of curing reaction: |

|

|

| Fig. 3. Addition curing

of DEHESIVE® silicone rubber (Source:

Ref. [11], p. 41) |

|

|

| Fig. 4. Condensation

curing of DEHESIVE® silicone rubber (Source:

Ref. [11], p. 41) |

|

In addition curing,

the hydrogen atoms from the Si-H groups add across the vinyl

groups of the polymers. Condensation curing also involves the

active Si-H groups from the crosslinking agent, but in this

case hydrogen is split off. In both cases, the silicone macromolecules

are linked together to form a network. The resultant material

adheres well to cellulose or glass, the polar sections of the

silicone molecules interacting (dipole-dipole and hydrogen

bonds) with the substrate. The methyl groups of the silicone

molecules project outwards (see also the experiment "Hydrophobic

properties of silicone fluids").

As a result, the silicone on the paper has a non-stick effect

or release effect on common adhesives, i.e. the adhesive either

bonds weakly or not at all to the silicone layer. This behavior

is due to the weak forces of interaction (Van der Waals) between

the molecules of the adhesive and the methyl groups of the silicone.

The unusually weak intermolecular bonding forces are also found

when the surface tension (surface energy) of silicones is compared

with that of other organic polymers, all of which have higher

surface energies (Table 3).

|

|

| Polymertyp |

Surface

tension in [mNm-1] |

Polydimethylsiloxane |

21-22 |

Polyphenylmethylsiloxane |

26 |

Polyvinylchloride |

40 |

Polyethylene |

30 |

Starch |

40 |

Wool |

45 |

|

| Table 3: Surface tension

of various polymers (Source:

Ref. [2], p. 59) |

|

6

References 6

References |

| |

W. Held et

al., Learning by Doing – School Experiments with WACKER

Products (handbook accompanying WACKER's Experimental Kit), Wacker Chemie AG,

Munich, 2007, p. 40 - 42 |

|