Silicones

for Paints Silicones

for Paints

Modern paints are expected to offer a range

of effects from hammer-effects to special textures. Paints

have to adhere well to different substrates. Printing inks

and paints should not foam more than necessary during manufacture

and application. And it is desirable for waterborne dyes to

be used wherever possible.

Silicone additives can meet all these requirements. Automotive

finishes illustrate this well. An automotive finish has to

meet esthetic requirements in addition to protecting the bodywork.

Colorfastness and lasting gloss are key quality determinants

here. The difference between good gloss and poor gloss is shown

in the following diagram:

Irregularities in the surface structure

of paint during finishing have various causes. These include

foaming as the paint is being sprayed and uneven evaporation

of the solvent during the drying process.

Foaming Foaming

The finishes are sprayed in fine jets under

high pressure by automatic painting equipment. Turbulence of

the micro-droplets can cause air bubbles to be trapped, and

this can lead to flaws in the finish. With increased use of

solventless, waterborne surface-coating systems, foaming also

occurs. It is caused by the surfactants contained in the waterborne

solvents. The counter-measure is to admix silicone-based foam

inhibitors. These lower the surface tension so much that the

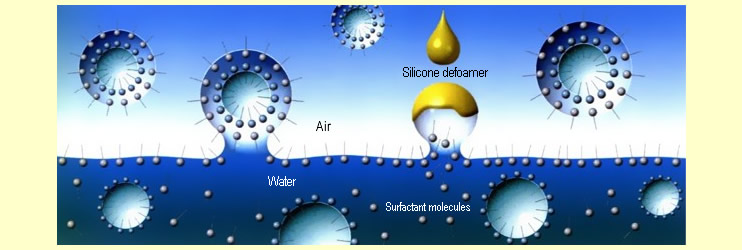

foam literally collapses. The following diagram time shows

how a silicone foam-control agent works (see also the experiment “Silicones

for antifoams”):

|

Bubbles are formed

when surfactant molecules accumulate at the boundary surface

to air, lowering the surface tension of the water and trapping

air. Provided that the surfactant doesn't drain away, the

bubbles will remain stable for quite a long time. Since

the silicone antifoams have a lower surface tension than

even the surfactants, they take their place. The foam lamella

becomes thinner as a result, becomes unstable and then

collapses.

Silicone antifoams are used wherever excessive

foaming is unwanted. Even in modern detergents.

|

Solvent

Additives Solvent

Additives

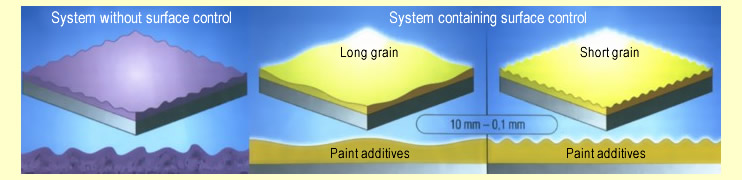

As already mentioned, uneven evaporation

of the solvent causes irregularities in the finish. Differences

in surface tension lead to cratering by dust particles, poor

wetting of the substrate, poor mar resistance as well as flow

problems. These effects are combated by admixing silicone additives

to lower the surface tension of the paint and increase its

spreading properties. The microscopic ripple structure of the

paint becomes smoothed, incident light is reflected better

and the desired gloss effect is obtained. This shown in the

following diagram:

|

Without appropriate additives,

the dried paint surface is irregular and rough (left

diagram).

The

appropriate additives ensure that the surface appears

uniform and smooth. It is possible to create “long-wave” and “short-wave” ripple

structures by varying the type and quantity of additive

(right diagrams). |

Heat-Resistant

Paints Heat-Resistant

Paints

Silicone-based paints have enough durability and fastness

to meet extreme demands. They are ideal for objects that have

to withstand high temperatures. These include barbecues and

all kinds of stoves as well as colored light bulbs and space

rockets.

The paint must be non-flammable, non-oxidizable and offer adequate

adhesion across all temperature ranges. Silicone

resins meet

all these requirements. A broad range of colors can be produced

by adding heat-resistant inorganic pigments . See also the

videos on this (wmv or mov).

Three Typical Applications of Heat-Resistant

Paints Are Shown Below: |

|

|