Pyrogenic

Silica for Thixotropic Liquids Pyrogenic

Silica for Thixotropic Liquids

What have pyrogenic silicas (HDK®)

to do with silicones? Well, for one thing, HDK® is

used for precisely adjusting the desired properties of silicones

(see below). For another, the production of these products

is closely linked to the Manufacture

of silicones at WACKER. When

chlorosilanes (tetrachlorosilane and

others), which are essentially unwanted volatile by-products

of the silicones

production process, are introduced into a hydrogen flame, they

react with water formed in situ to

produce pyrogenic silica (HDK®),

whose composition approximates to SiO2:

SiCl4 + 2H2 + O2 ® SiO2 +

4HCl

A carefully controlled process and short contact time in the flame

ensures that the silica is produced in the form of nano-particles.

Since this synthetic silica is formed in a flame and is a white powder,

it is also referred to as white carbon black. Its configuration and

properties are discussed in detail below.

First, though, let us explain what a thixotropic material is:

|

Silicone rubber, which is used for insulating

metal wires and glass fibers, may contain up to 40 % pyrogenic silica.

Here, the HDK® ensures that the vulcanized silicone

rubber becomes an elastic material that has excellent mechanical

properties.

The flow properties of paints and coatings can be controlled precisely with pyrogenic silica. HDK® is accordingly used in modern paints and coatings as a rheological additive. |

|

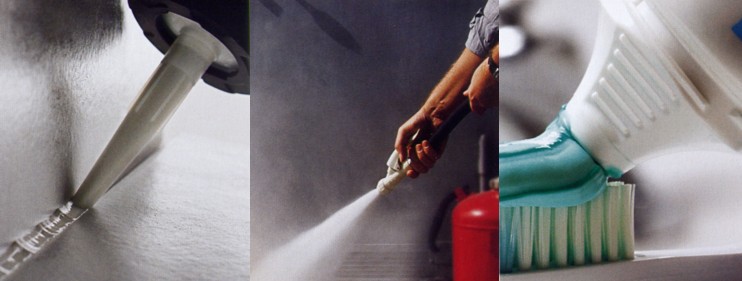

HDK® is used as an active filler in joint sealants and as a free-flow agent in fire extinguisher powders. In toothpastes, its function is to impart the desired consistency. HDK® is used as an active filler in joint sealants and as a free-flow agent in fire extinguisher powders. In toothpastes, its function is to impart the desired consistency. |

|

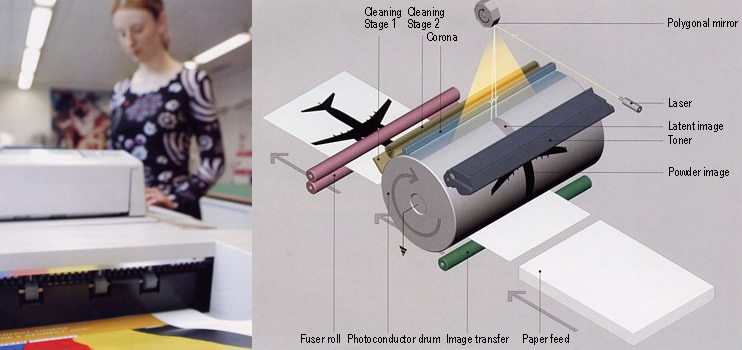

| In modern laser printers, a latent, invisible image is first written with light on an electrically charged photoconductor. The toner powder particles must “sense” the charge differences in the latent image, such that they are deposited in certain places but not in others. The result is the powder image, which, in a subsequent step, is transferred to the paper and then fixed by fusing. Strict demands are made on the toner in respect of its free-flow quality and its electrical and thermal properties. Small additions of HDK® pyrogenic silica to the toner make it possible to regulate its free-flow property, so that HDK® effectively “fine-tunes” the toner in laser printers. |

|

|

Structure

and Properties of Pyrogenic Silica Structure

and Properties of Pyrogenic Silica |

|

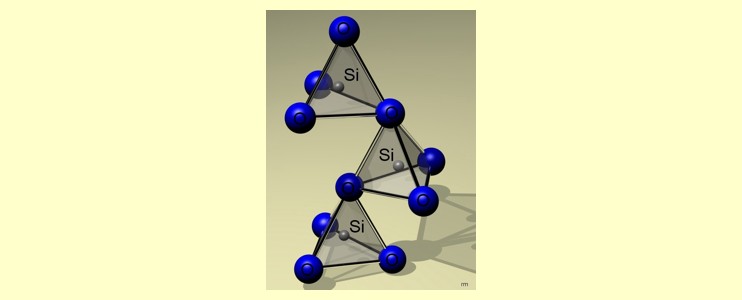

| Pyrogenic silica is a very efficient thixotropic

agent. This property is based on its structural characteristics.

Although it has essentially the same composition as sand and

quartz , structural differences exist. The following model of

the atomic lattice of silica shows that every silicon atom is

surrounded by four covalently bonded oxygen atoms: |

|

In

sand and quartz, these SiO4-SiO4 tetrahedra

are regularly arranged in a three-dimensional crystal lattice,

but in a primary

particle of pyrogenic silica they form a disordered amorphous system.

A primary particle contains about 10.000 SiO2 units

and is a so-called nano-particle with a diameter between 5 and

30 nm (1 nm = 10-9 m).

The outwardly projecting oxygen atoms are bonded to hydrogen

atoms. So a primary particle is like a hedgehog whose spines

consist of -OH groups These groups render the surface of a primary

particle hydrophilic because they can form hydrogen bonds with

water molecules. However, they also cause many stationary primary

particles to form extensive three-dimensional networks through

aggregation (aggregates of nano-particles). In

sand and quartz, these SiO4-SiO4 tetrahedra

are regularly arranged in a three-dimensional crystal lattice,

but in a primary

particle of pyrogenic silica they form a disordered amorphous system.

A primary particle contains about 10.000 SiO2 units

and is a so-called nano-particle with a diameter between 5 and

30 nm (1 nm = 10-9 m).

The outwardly projecting oxygen atoms are bonded to hydrogen

atoms. So a primary particle is like a hedgehog whose spines

consist of -OH groups These groups render the surface of a primary

particle hydrophilic because they can form hydrogen bonds with

water molecules. However, they also cause many stationary primary

particles to form extensive three-dimensional networks through

aggregation (aggregates of nano-particles). |

|

| Fluids or gases can be stored and largely

immobilized in the interstitial space of these aggregates. If

the liquid is water or an aqueous solution, hydrogen bonds are

formed between the water molecules and the -OH groups on the

surface of the silica particles. In this state, the system is

viscous to solid on a macroscopic scale. Mechanical stress, such

as shaking or stirring, temporarily disturbs the silica nano-particle

aggregates. This ruptures some of the hydrogen bonds holding

the particles together. Macroscopically, the system becomes free-flowing

(thixotropic effect). The longer the external force acts, the

more bonds are ruptured and the "more fluid" the material

becomes. When the force stops, three-dimensional aggregates are

re-formed and the material becomes viscous to solid again (see

diagram above). |

|

|