Silicones

for Textiles Silicones

for Textiles

Thanks to their excellent properties, silicones

are widely used in the textile industry. Water-repellent treatment

causes rain to run off in little beads. Yet the fabric can

still breathe, so sufficient air still reaches the skin. Pigment

prints only really come into their own when silicones are used.

They also prevent felting of wool, as well as being used as

softeners.

|

|

|

| When colored textile fabrics

are treated with silicones, their colors look more vivid.

The silicones render the surface smoother and light is

reflected less diffusely. |

|

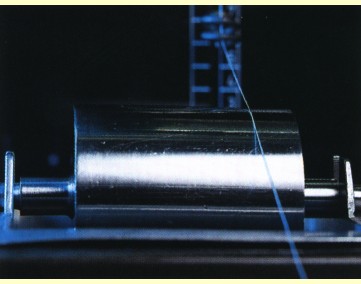

Impregnation with silicone

lubricant has smoothed the surface of the sewing thread.

The thread can now be processed much more easily than an

untreated thread. |

|

Softeners Softeners

Another important application of silicones for textiles is as softeners. Long-chain polydimethylsiloxanes with amino-functional side groups are best suited for this purpose. The amino groups anchor the silicone to the fiber by way of attractive electrostatic forces. Interfiber friction is reduced in this way, producing the desired softener effect. Silicone applied as a microemulsion can penetrate into the fiber, making it stronger and increasing its volume.

For towels, the hydrophobic property of silicones is undesirable. Towels should of course be soft and fleecy, but they must be able to absorb sufficient moisture. In order to satisfy both requirements, the silicones used here have a cyclohexyl group attached to the amino group. These silicones are also characterized by good heat resistance, which is important for industrial drying.

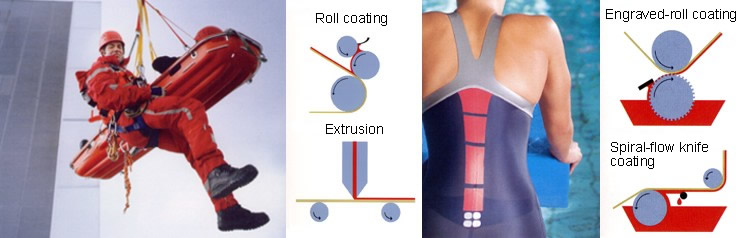

Siliconized textile coatings on tenting, protective clothing, sports clothing and airbags have to meet extremely tough requirements. Textile coatings are therefore tailored jointly by our globally active WACKER team and our customers from the textile industry. ELASTOSIL® silicone rubber grades are often used for this application. The silicone rubber is usually applied to the fabric by roll-coating or extrusion. |

|

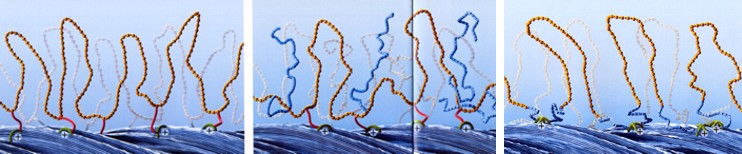

Innovative silicones are also available which are used as textile softeners. These silicones are characterized structurally by polydimethylsiloxane chains with amino side groups. During the rinse cycle, these mainly form positively charged ammonium ions that anchor the silicone macromolecule to the fiber. Innovative silicones are also available which are used as textile softeners. These silicones are characterized structurally by polydimethylsiloxane chains with amino side groups. During the rinse cycle, these mainly form positively charged ammonium ions that anchor the silicone macromolecule to the fiber. |

|

| The silicone fragments (side loops) move easily, are hydrophobic, and all point away from the fiber (left-hand picture). They impart the soft hand. In order to obtain a textile surface that is wettable with water, polyglycol side chains (center picture, blue) can be incorporated into the silicone molecule. These form channels through which water molecules can get to the fiber surface. In WACKER® SLM 21200 silicone softener, the macromolecules are built up in such a way that the polyglycol chains are attached directly to the fiber surface (right-hand picture). The silicone loops, by contrast, remain pointing away from the fiber and can move freely. Thus, textiles treated in this way have the soft hand typical of silicones but can also readily soak up water. |

|

| Textiles can be rendered crease-resistant and easy to iron with WACKER® FC 201, a silicone/polyglycol copolymer. Here too, amino groups provide for anchorage to the fiber, polyglycol chains for the hydrophilic properties and silicone loops for the soft hand and crease resistance. |

|

|

|